Wide Range of Capabilities

Our Manufacturing Expertise

Our diverse manufacturing capabilities allow us to select the optimal production method for your specific application requirements, ensuring quality, cost-effectiveness, and performance. These have been built upon the premise that we will do everything in our power to say "YES" to the customer.

Contact us now to discuss how our manufacturing expertise can deliver superior solutions for your rubber and polymer component needs.

Compression Molding

As a recognized industry leader in compression molding, we specialize in producing durable, high-performance rubber components designed to meet demanding specifications.

This process delivers exceptional consistency, durability, and reliability for complex parts across automotive, aerospace, medical, and industrial applications. Ideal for large, heavy-duty components, parts requiring superior mechanical performance, and complex geometries with tight tolerances.

Transfer Molding

Our precision transfer molding delivers high-performance rubber components with tight tolerances and exceptional quality.

This method excels in producing intricate parts with complex geometries, undercuts, and embedded metal inserts, serving industries that demand dimensional stability and superior detail reproduction. Perfect for electrical connectors, specialized seals, and components requiring minimal material waste with consistent performance.

Injection Molding

We specialize in high-precision rubber injection molding, providing efficient, high-volume production of complex components.

This advanced process creates intricate parts with thin walls, fine details, and complex geometries while ensuring uniform material distribution and fast cycle times. Ideal for high-volume production runs requiring exceptional part-to-part consistency and precise dimensional stability.

Overmolding

Our advanced overmolding solutions integrate rubber with materials like plastics, metals, and composites to create high-performance components with enhanced functionality.

This specialized process creates strong bonds between materials, offering benefits like vibration damping, shock absorption, chemical resistance, and environmental sealing for industries including automotive, medical, aerospace, and industrial equipment.

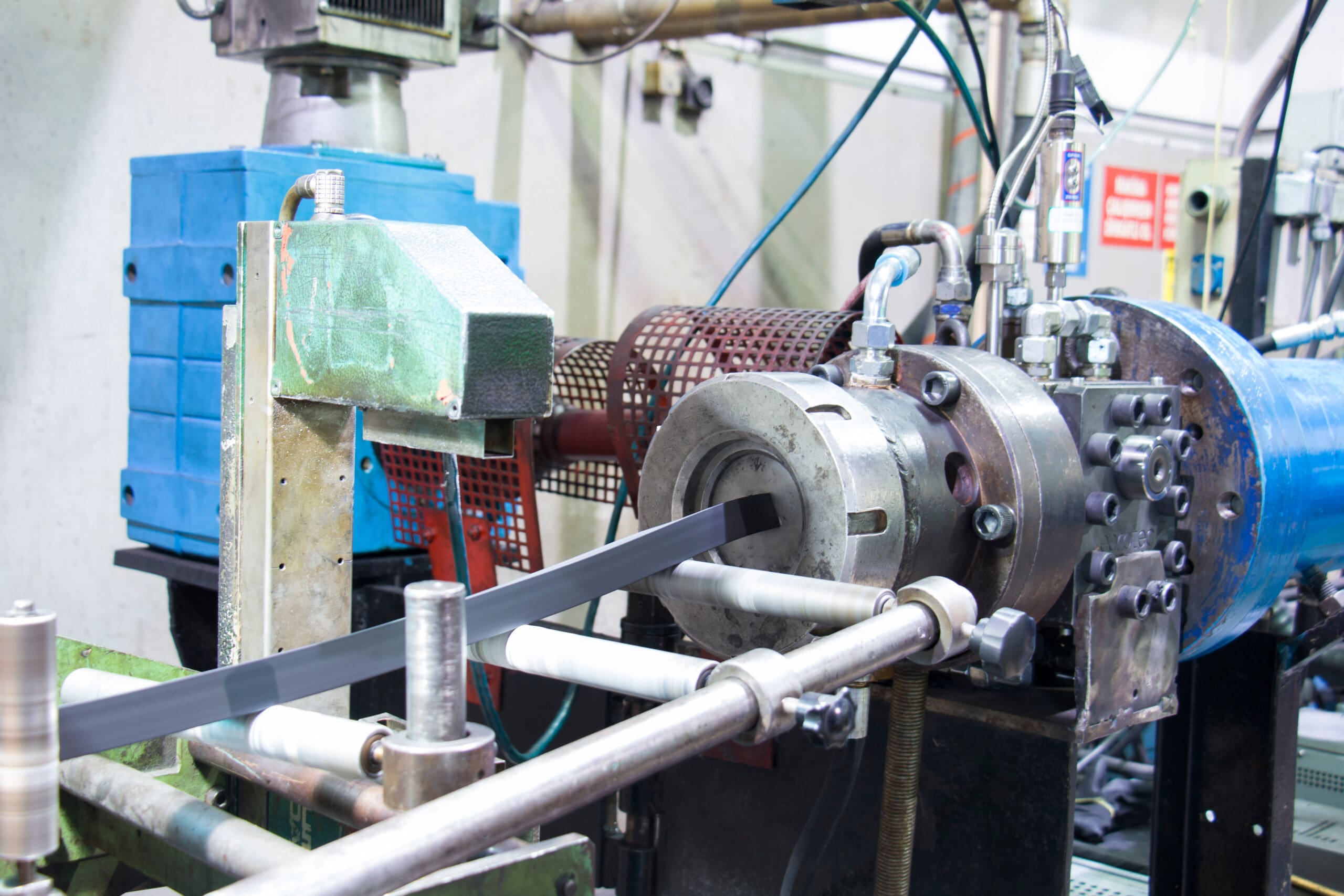

Extrusion

We complement our molding expertise with rubber extrusion capabilities, producing custom elastomeric profiles, tubes, and seals with exceptional consistency.

This versatile process creates continuous-profile components with uniform cross-sections for both high-volume production and specialized applications. Ideal for linear seals, custom profiles, and components requiring precise dimensional stability across their length.

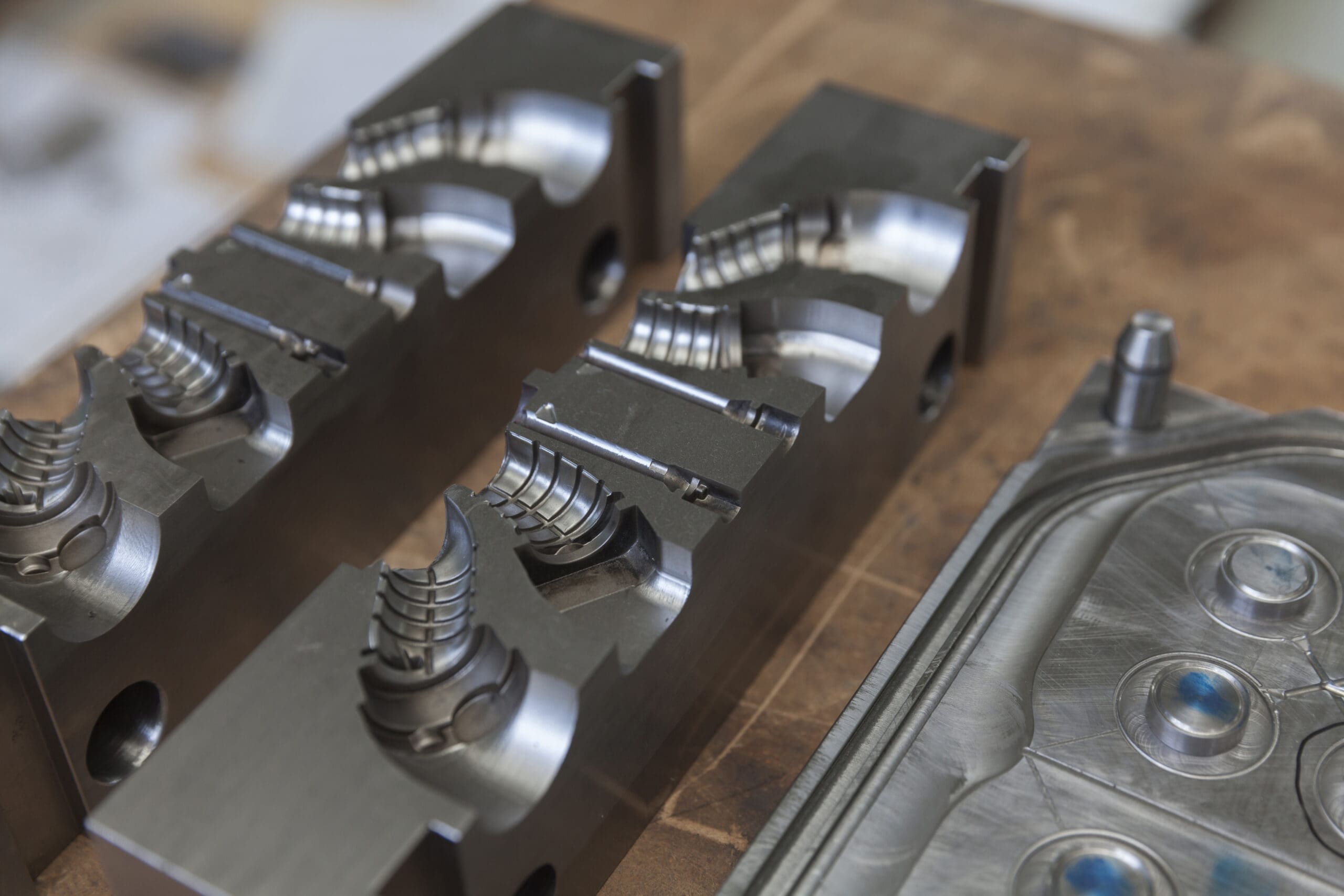

Mold Making

Our in-house moldmaking capabilities provide complete control over the design, development, and production of precision-molded rubber components.

This integrated approach enables faster turnaround times, improved product performance, and greater flexibility in material selection and part geometry. Our advanced engineering and CAD/CAM expertise optimize mold designs for cost efficiency and superior quality.

Metal Stamping

We combine advanced metal stamping with rubber manufacturing expertise to produce highperformance hybrid components.

Using compound die technology and precision equipment, we transform metals like steel, stainless steel, and aluminum into complex components with tight tolerances, then precisely bond them with rubber for enhanced durability and performance in demanding applications.

Die Cutting

Our precision die cutting services produce high-quality rubber components like gaskets, seals, and washers with exceptional accuracy.

Using precision-engineered metal dies, we efficiently create high-volume or custom, low-run parts with clean, precise edges and consistent dimensions. Ideal for flat components requiring tight tolerances and clean-edged shapes across various industries.

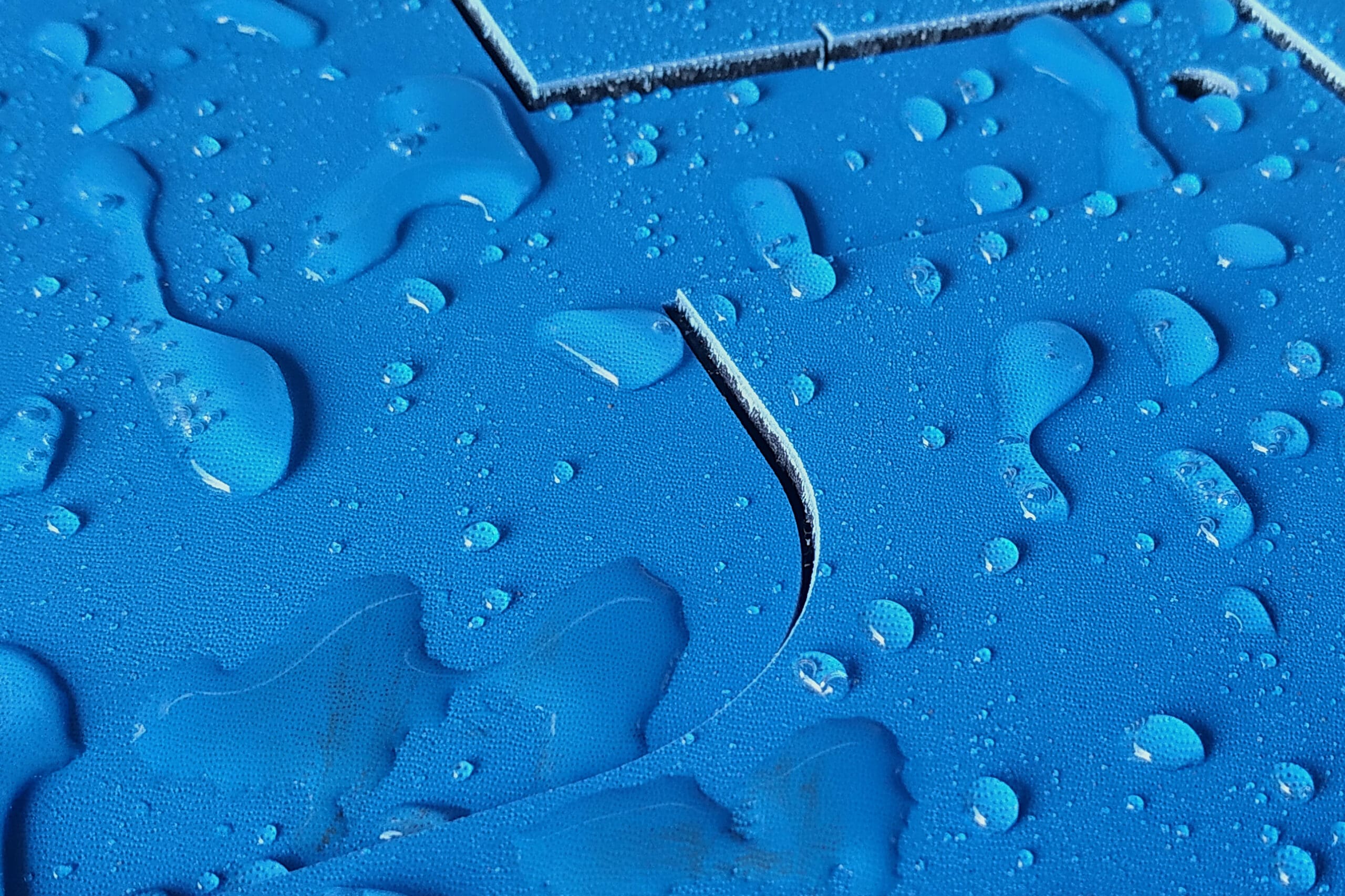

Waterjet Cutting

We utilize advanced waterjet cutting technology to produce highly precise, intricate rubber components with tight tolerances and clean edges.

This versatile method avoids the thermal effects of traditional cutting, preserving material properties while achieving exceptional accuracy for complex geometries. Perfect for intricate parts with multiple internal features and tight curves requiring tolerances as tight as ±0.005 inches.