What’s the difference between durometer and modulus for molded rubber products? Durometer is a measure of a rubber’s resistance to indentation. More commonly, however, it’s known as a measure of hardness. Modulus is the stress or force that’s required to produce a strain, the change in length or shape when a force is applied, divided by the original length or …

Flashless Rubber Molding

Flashless molding uses precision tooling to mold rubber parts with only small amounts of flash. The tooling is more expensive, but flashless molds reduce costs over time by eliminating secondary operations.

Reshore to Restore: Building a Resilient Supply Chain

Reshore to restore competitiveness and eliminate uncertainty. Build a resilient supply chain for molded products with the Rubber Group.

Flashless Medical Molding for Rubber Products

Flashless molding uses precision tooling to mold rubber parts with only small amounts of flash. The tooling is more expensive, but flashless molds reduce costs over time by eliminating secondary operations.

AS9100D Certification Reinforces TRG’s Commitment to Quality

The Rubber Group is proud to confirm our commitment to quality in the Aerospace, Space, and Defense (ASD) sectors by successfully maintaining conformance to the AS9100D standard.

TRG Receives Trademark for MedElast USP VI Silicone Rubber

TRG’s medical silicone complies with USP Class VI requirements for biocompatible elastomers that are safe for use when contact with human tissues and fluids is possible.

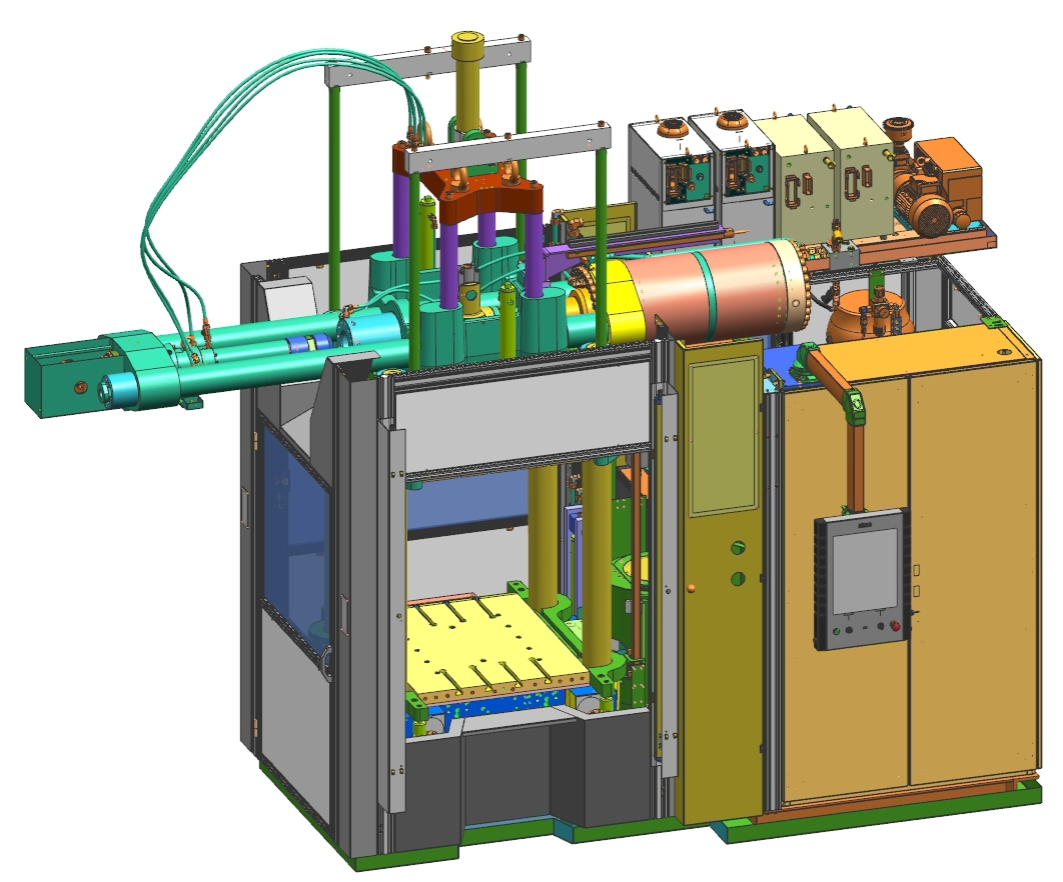

Large Part Injection Molding

The Rubber Group uses a DESMA 968.400 ZO Benchmark (S2) for large part injection molding.

PFAS Reporting Update

This PFAS Reporting Update contains information for manufacturers, importers, and other receivers of PFAS-containing elastomers like FKM, Viton, FVMQ, and FFKM.

TRG Engineer Completes ARPM Seal Design and Manufacturing Course

Jacob Mancini, TRG Product & Mold Design Engineer, recently completed the ARPM Seal Design and Manufacturing Course. He described the class as “phenomenal”.

Rubber Compression Molding: An Introduction

Rubber compression molding produces elastomeric parts by placing a pre-measured amount of rubber into a mold, closing the tool, and applying heat and pressure.