Company Profile and Capabilities

Learn about our history, certifications, and commitment to your success. From engineering and logistics through manufacturing and distribution, The Rubber Group is the industry leader in custom molded rubber products for major OEMs with names that you’ll recognize.

Terms and Conditions

Read The Rubber Group's Terms and Conditions . Updated November 2020.

Chemical Compatibility

Find out which chemicals are compatible with natural rubber, SBR, GRS, butyl, EPR, EPT, EPDM, nitrile, Hydrin®, neoprene, Hypalon, urethane, polysulfide, silicone, fluorosilicone, and fluoroelastomers. From acetaldehyde to zinc sulfate, you’ll find the information that you need.

Molding Tolerances

Look up dimensional tolerances for A1 High Precision, A2 Precision, and A3 Commercial drawings from the Association for Rubber Product Manufacturers (ARPM) handbook. Each drawing designation includes millimeter and inch-based measurements for fixed and closure dimensions.

Flash and Surface Finish

Find flash and surface finish classes for molded rubber parts. Flash, the excess rubber resulting from cavity overflow, is common in rubber molding. The machined finish of a metal mold has a signficant effect on the surface finish or appearance of molded rubber products.

Shelf Life for Cured Rubber

Find guidelines and best practices for defining the shelf life of various rubber polymers and subsequent evaluation on the effects of aging on the materials as well as the best practices for storage to maximize the shelf life of all parts

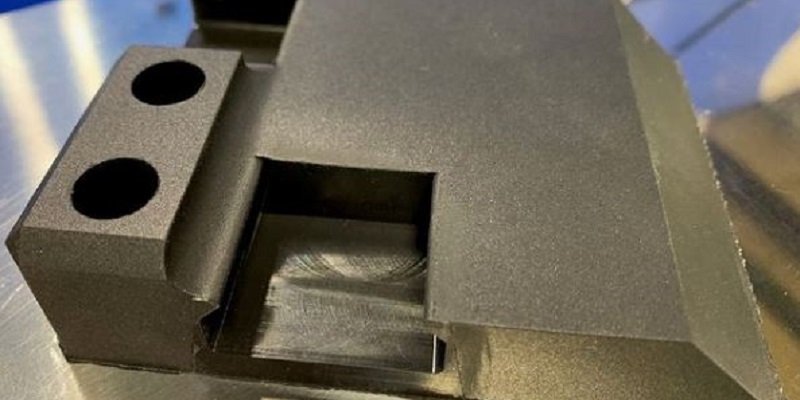

Video: DESMA Animated Operations

The Rubber Group is using its new DESMA 968.400 ZO (S2) benchmark press to produce large rubber parts like insulators for power transformers. DESMA, the press manufacturer, is a leading provider of injection molding equipment for technical rubber and silicone molded articles.