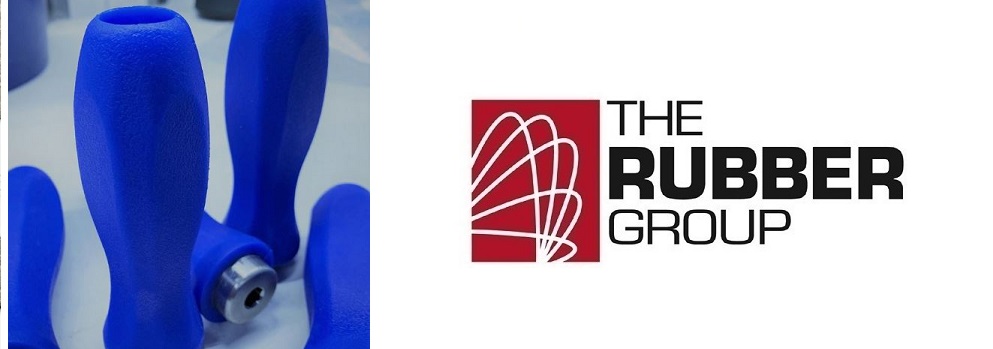

Medical handles that use rubber overmolding contribute to the safety of patients and the well-being of healthcare workers. They improve comfort and gripping.

ISO 10993 vs. USP Class VI: Medical Molding and Biocompatible Rubber

ISO 10993 and USP Class VI both define testing requirements for biocompatibility. Learn about the differences between them so you can select the right rubber.

Medical (USP Class VI) Injection Molding for Rubber Products

Medical injection molding (USP Class VI) for rubber products provides USP Class VI biocompatibility with control and consistency across high volumes of parts that require medium-to-high levels of precision.

USP Class VI Elastomers: Use Fully Tested Materials

The Rubber Group sources and molds fully-tested and certified USP Class VI elastomers for medical, healthcare, pharmaceutical, and biopharma products.

Sterilization Mats for Medical Devices, Surgical Instruments and Dental Tools

The Rubber Group molds standard and custom silicone sterilization mats for medical, surgical, and dental customers in various colors, sizes, and features.

FKM Shortages: How to Prevent Supply Chain Interruptions

Medical transfer molding provides tight control of part tolerances and can fill hundreds of mold cavities from a single pre-formed material. For both short runs and high volumes, this flexible manufacturing method supports complex shapes, thin-walled parts, and consistent dimensions.

Medical Transfer Molding for Rubber Gaskets and Rubber Products

Medical transfer molding provides tight control of part tolerances and can fill hundreds of mold cavities from a single pre-formed material. For both short runs and high volumes, this flexible manufacturing method supports complex shapes, thin-walled parts, and consistent dimensions.

Medical Compression Molding for Rubber Gaskets and Rubber Products

Medical compression molding can produce cost-effective rubber gaskets and rubber products for medical devices and equipment. It’s a good choice for very hard or difficult-to-flow materials because this molding method doesn’t need to push the rubber through sprues, gates, or runners.

Three Types of Medical Molding for Rubber Gaskets and Rubber Products

Medical molding for rubber gaskets and rubber products offers medical device designers a choice of molding methods: injection, transfer, or compression molding.

Medical Rubber Molding and Process Validation for Critical Parts

Medical rubber molding and process validation for critical parts includes protocol development, SPC and process capability, IQ/OQ/PP, and proof of regulatory compliance.

- Page 1 of 2

- 1

- 2