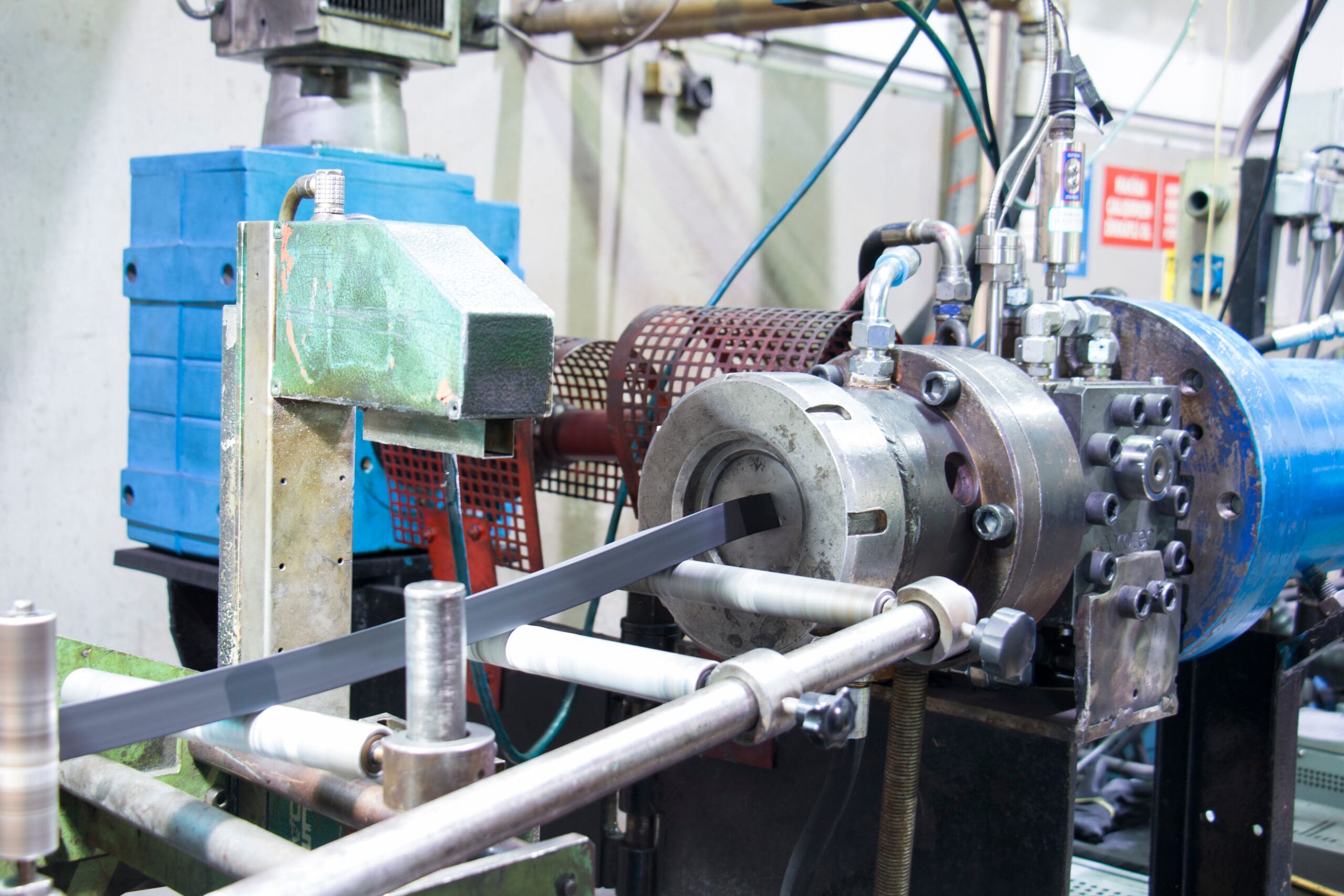

Rubber Extrusion

The Rubber Group complements its molding expertise with rubber extrusion, producing custom elastomeric components like profiles, tubes, and seals with precise accuracy, durability, and reliable performance for various industries

The Rubber Group enhances its molding expertise with rubber extrusion, producing

continuous-profile elastomeric components such as custom profiles, tubes, and

seals with exceptional consistency and quality. This versatile process, ideal for both

high-volume production and specialized extrusions, serves industries like

automotive, aerospace, medical, and construction. The extrusion method forces

uncured rubber through a precisely designed die, creating components with uniform

cross-sections, followed by curing to improve properties like strength and chemical

resistance.

Our expertise in material selection, process optimization, and die design

ensures durable, high-performance components tailored to specific requirements.With secondary processing options like cutting and bonding, we provide reliable,

cost-effective solutions for a wide range of applications.

Pros (Ideal for):

- Continuous-profile elastomeric components

- Products requiring uniform cross-sectional designs

- Linear seals with precise dimensional stability

- High-volume or custom production runs

Specific Industry Applications:

- Aerospace sealing components

- Medical tubing and profiles

- Construction sealing elements

- Appliance manufacturing gaskets

- Vibration isolation profiles

- Custom continuous rubber components

Limitations

- Limited to linear, continuous designs

- Not ideal for highly complex cross-sections

- Less suitable for intricate 3D shape

- Potential material waste in short runs

- Requires specialized die design

- Less flexible for rapid design iterations

Decision Factors / Comparative Manufacturing:

- Better for complex 3D parts: Molding techniques

- More suitable for short components: Compression or injection molding

- Superior for long, linear components: Extrusion