Gasket Solutions

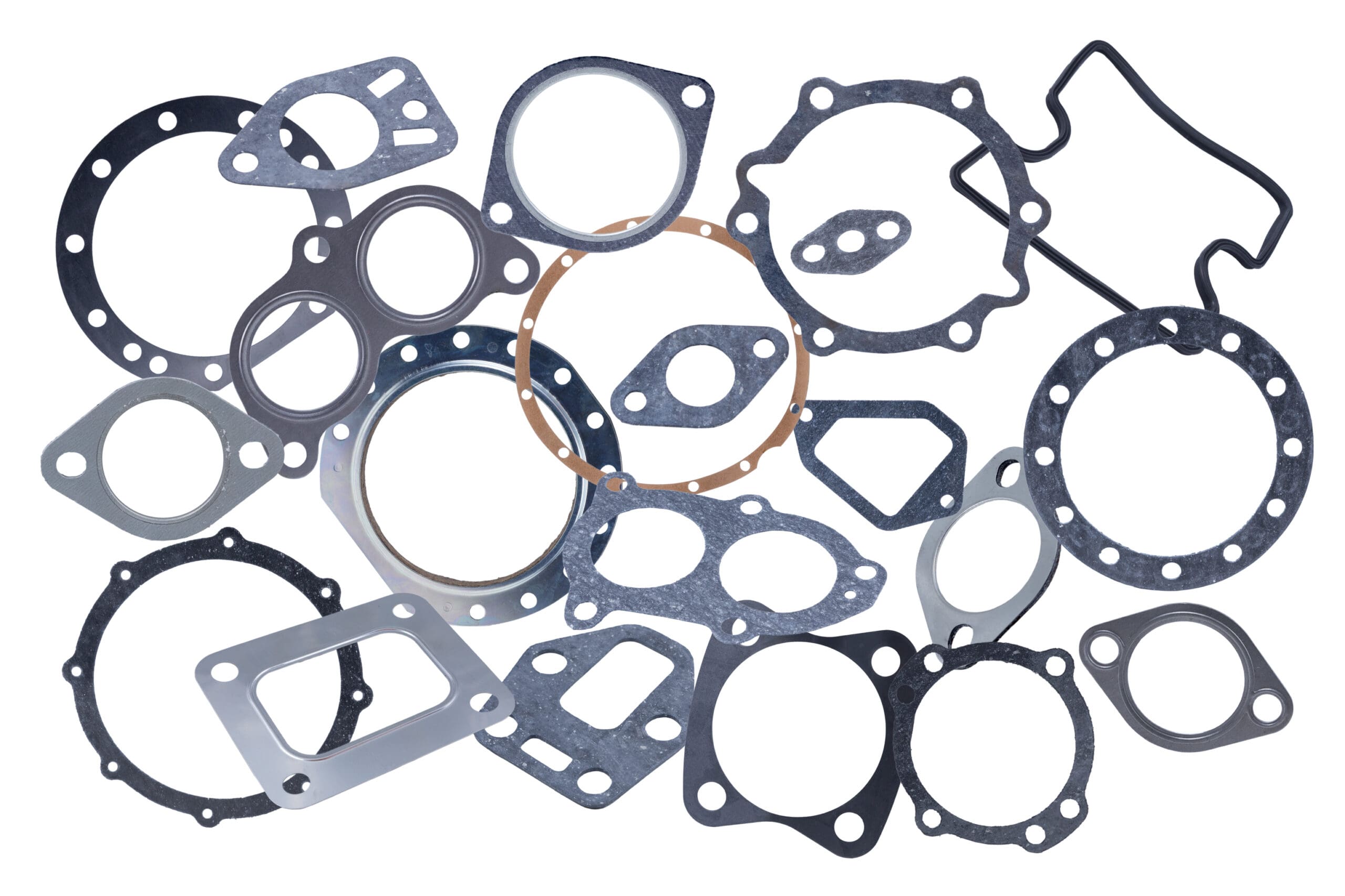

Custom Gasket Solutions - Engineered for Performance Precision Gaskets for Every Application

We engineer and manufacture premium custom gaskets that deliver reliable sealing performance across the most demanding industrial applications. With decades of experience and advanced manufacturing capabilities, we provide precision-engineered gasket solutions that help our customers prevent leaks, reduce downtime, and extend equipment life.

Material Expertise That Exceeds Expectations

Our comprehensive material science capabilities ensure you receive the optimal gasket solution for your specific application requirements:

Premium Materials

- EPDM - Superior weathering, ozone, and steam resistance for outdoor applications and water systems

- Nitrile (NBR) - Outstanding oil and fuel resistance from -65°F to +250°F for hydraulic and petroleum applications

- FKM (Viton®) - Exceptional chemical and high-temperature resistance up to 500°F for aggressive processing environments

- Silicone - Extreme temperature performance (-120°F to +450°F) with excellent compression recovery for thermal cycling applications

- FFKM (Perfluoroelastomer) - Ultimate chemical resistance for the most aggressive environments where other elastomers fail

- HNBR - Enhanced heat and chemical resistance with superior physical properties for demanding oil & gas applications

- Neoprene - Excellent balance of properties including weather, oil, and flame resistance for versatile industrial applications

- Specialty Compounds - Custom-formulated materials addressing specific temperature, chemical, and physical requirements

- Virgin & Filled PTFE - Unmatched chemical compatibility with options for enhanced compression, reduced creep, and improved physical properties

Application-Specific Materials

- FDA/USDA Compliant - Food-grade materials certified for direct and indirect food contact

- USP Class VI - Ultra-pure materials for pharmaceutical and medical applications

- NSF/ANSI 61 - Certified materials for potable water applications

- UL-Listed - Flame-retardant materials meeting stringent safety requirements

- Conductive/EMI Shielding - Specialized materials for electrical applications requiring EMI/RFI protection

- Low Outgassing - Materials certified for semiconductor and vacuum applications

- Metal Detectable - Enhanced materials for food processing with foreign material detection capabilities

Manufacturing Excellence

Our state-of-the-art manufacturing facility combines precision equipment with skilled craftsmanship to deliver superior quality gaskets:

- Die Cutting - High-precision steel rule die and matched metal die cutting for exceptional accuracy

- Water Jet Cutting - Ultra-precise cutting technology for intricate designs and special materials

- Flash-Free Molding - Advanced compression and transfer molding capabilities for complex profiles

- In-House Tooling - Rapid tool design and production for custom configurations

Engineering Support & Custom Solutions

Partner with our experienced engineering team to optimize your gasket design:

Material Selection - Expert guidance on choosing the ideal material for your specific application

Custom Compound Development - Specialized formulations designed for your unique requirements

Design Assistance - Collaboration with your engineering team to enhance sealing performance

Problem-Solving Expertise - Solutions for challenging applications and environments

Prototype Development - Rapid sample production for testing and validation

Value Engineering - Cost-optimization without compromising performance