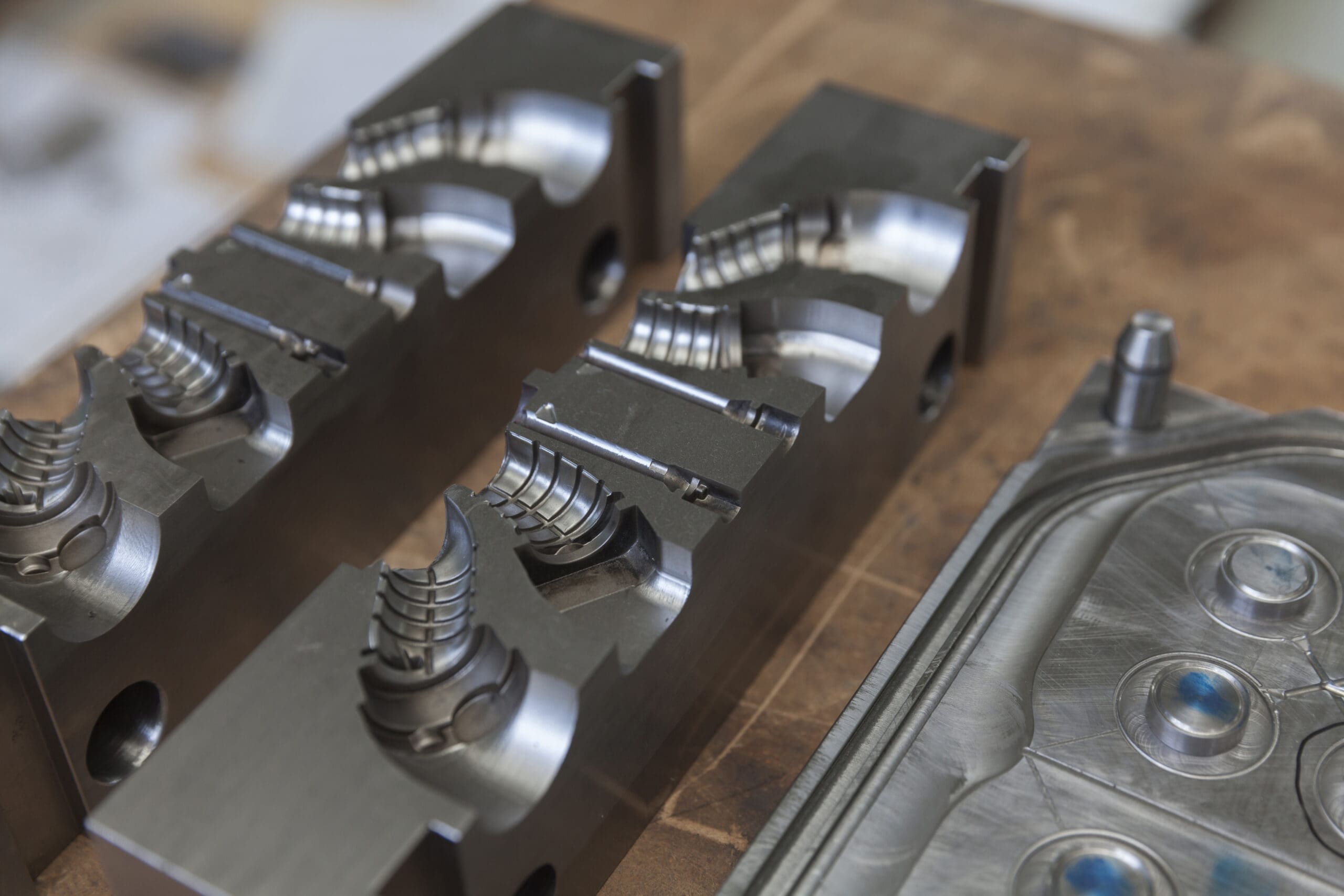

Mold Making

The Rubber Group’s custom moldmaking capabilities provide full control over design, development, and production of high-quality, precision-molded rubber components, ensuring faster turnaround times, improved performance, and flexibility for industries like automotive, aerospace, and medical.

The Rubber Group has integrated moldmaking into its operations, ensuring full

control over the design, development, and production of high-quality, precisionmolded rubber components. This capability enables faster turnaround times,

improved product performance, and greater flexibility in material selection and part

geometry for industries like automotive, aerospace, medical, and industrial

manufacturing.

The process involves advanced engineering, utilizing CAD/CAM

systems to create optimized mold designs. Our expertise in moldmaking contributes

to cost efficiency, reduced defects, minimized material waste, and quick

adjustments, ultimately delivering superior components that meet or exceed

customer expectations.

Pros (Ideal for):

- Complex rubber component manufacturing

- Parts requiring precise dimensional accuracy

- Consistent quality throughout production run

- Repeatable performance characteristics

- Low to high volume production

Limitations

- High initial tooling investment

- Longer initial design and development time

- Requires specialized engineering expertise

- Less cost-effective for extremely low-volume production

- Demands precise material and process understanding

- Complex modification process

Decision Factors / Comparative Manufacturing:

Superior for simple designs: Standard tooling

More suitable for rapid prototyping: Additive manufacturing

Better for complex, precise parts: Custom moldmaking