consistent performance

Engineered Elastomeric Solutions for Critical Applications

For over 30 years, The Rubber Group has specialized in custom-engineered elastomeric components that deliver precise, consistent performance in your most demanding applications.

When reliability is non-negotiable, our solutions ensure your systems function flawlessly. While this page highlights our core specialty products, our capabilities extend far beyond these offerings.

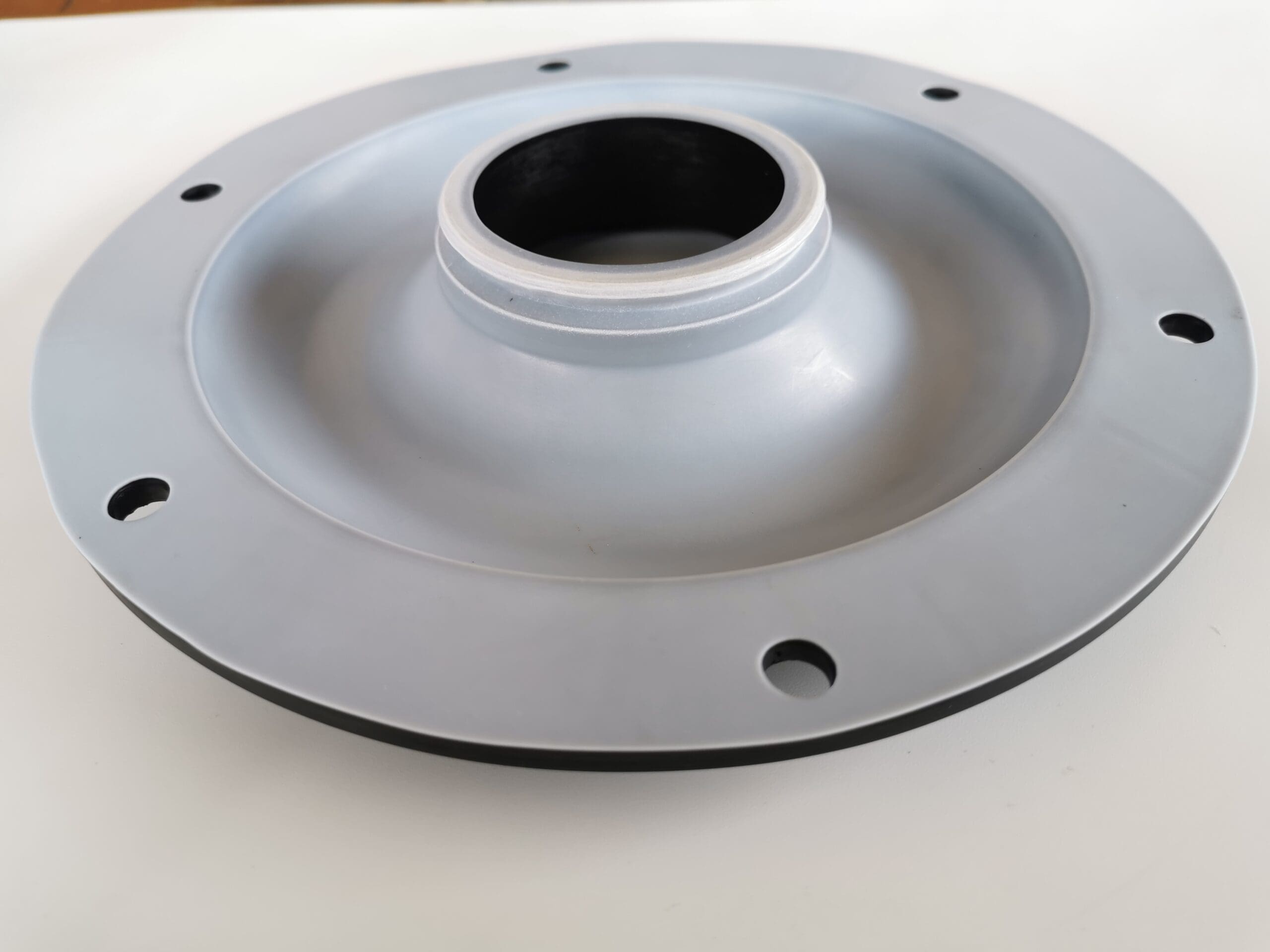

Diaphragms

Precision Flexible Barriers for Critical Applications

Engineered rubber and fabric-reinforced diaphragms for fluid control, sensing, and actuation applications. Our diaphragms maintain integrity under extreme pressure cycles, aggressive media exposure, and challenging operating conditions.

Bearing & Hub Seals

Advanced Protection for Critical Rotating Equipment

Custom-engineered bearing seals and shields that extend bearing life, prevent lubricant loss, and exclude contamination. Our precision-manufactured components deliver reliable performance in hostile environments, extreme temperatures, and high-speed operations.

Extruded Seals

Precision Sealing Solutions to Your Exact Specifications

Custom-engineered extruded rubber seals and profiles that deliver reliable environmental protection, vibration dampening, and gap sealing. Our advanced extrusion capabilities transform your requirements into precise, consistent sealing solutions.

Protection Boots

Engineered Protection for Mission-Critical Components

Custom-engineered rubber boots and bellows that protect your valuable mechanical systems from contamination, moisture, and premature wear. Our precision-molded products extend equipment life, reduce maintenance costs, and ensure reliable operation.

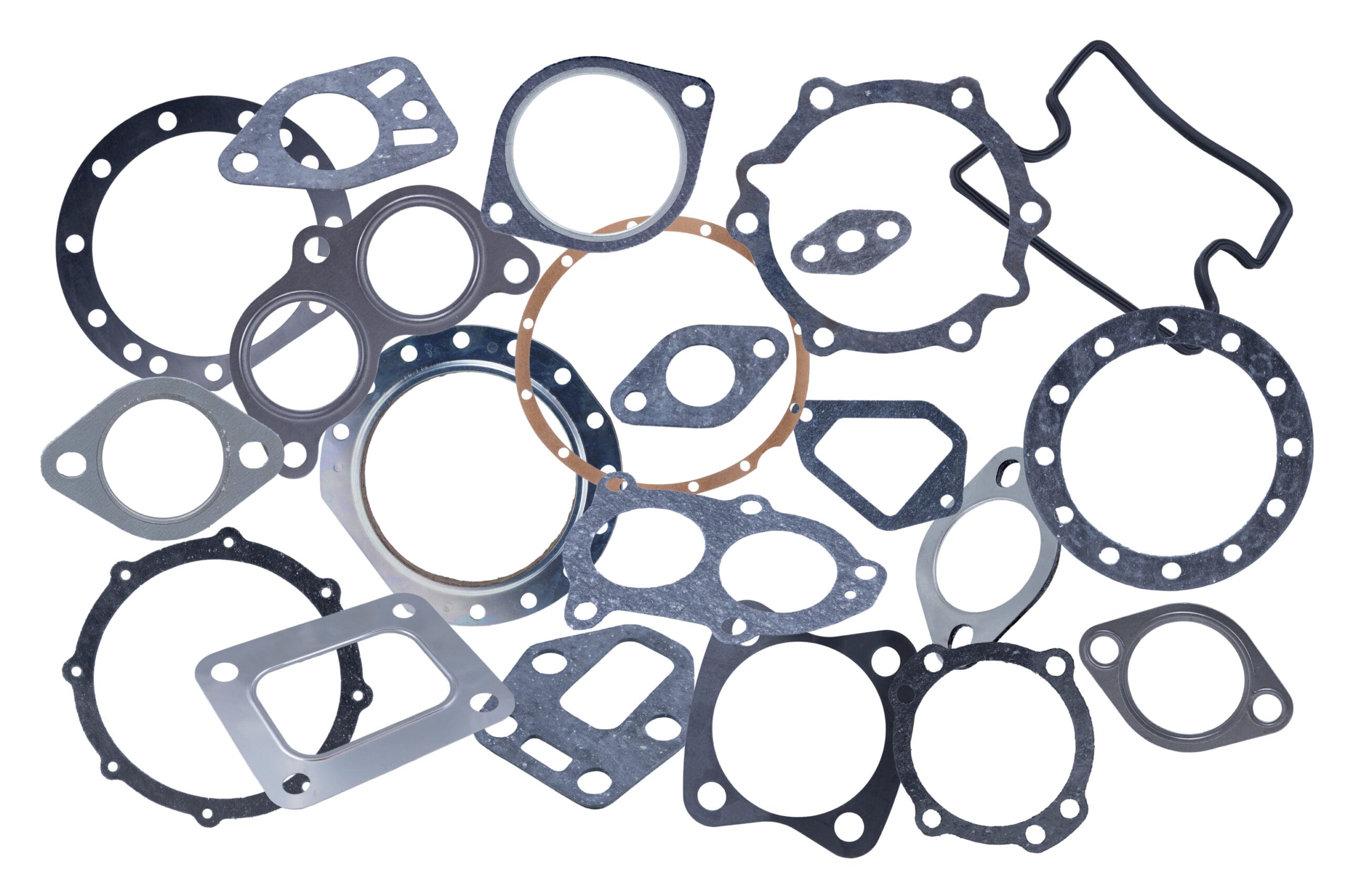

Gaskets

Engineered for Performance in Demanding Applications

Premium custom gaskets that deliver reliable sealing performance across the most demanding industrial applications. Our precision-engineered solutions help prevent leaks, reduce downtime, and extend equipment life.