Capabilities

Learn more about how we can be a complete solution provider.

Markets

See where we impact and make a difference.

Special Products

These are products that might be more challenging to source and set us apart.

Markets We Serve

Tailored for Your Industry

Aerospace & Defense

Aerospace & Defense

Our aerospace and defense solutions are engineered to withstand extreme environments where failure is not an option.

With ITAR registration and AS9100D certification, we deliver mission-critical components for aircraft, military vehicles, naval applications, and tactical equipment

Electrical T&D

Electrical Transmission & Distribution

Power infrastructure demands components that ensure decades of reliable service in challenging outdoor environments.

We produce custom insulator components, bushing seals, transformer gaskets, and switchgear sealing systems that maintain electrical isolation while resisting environmental degradation.

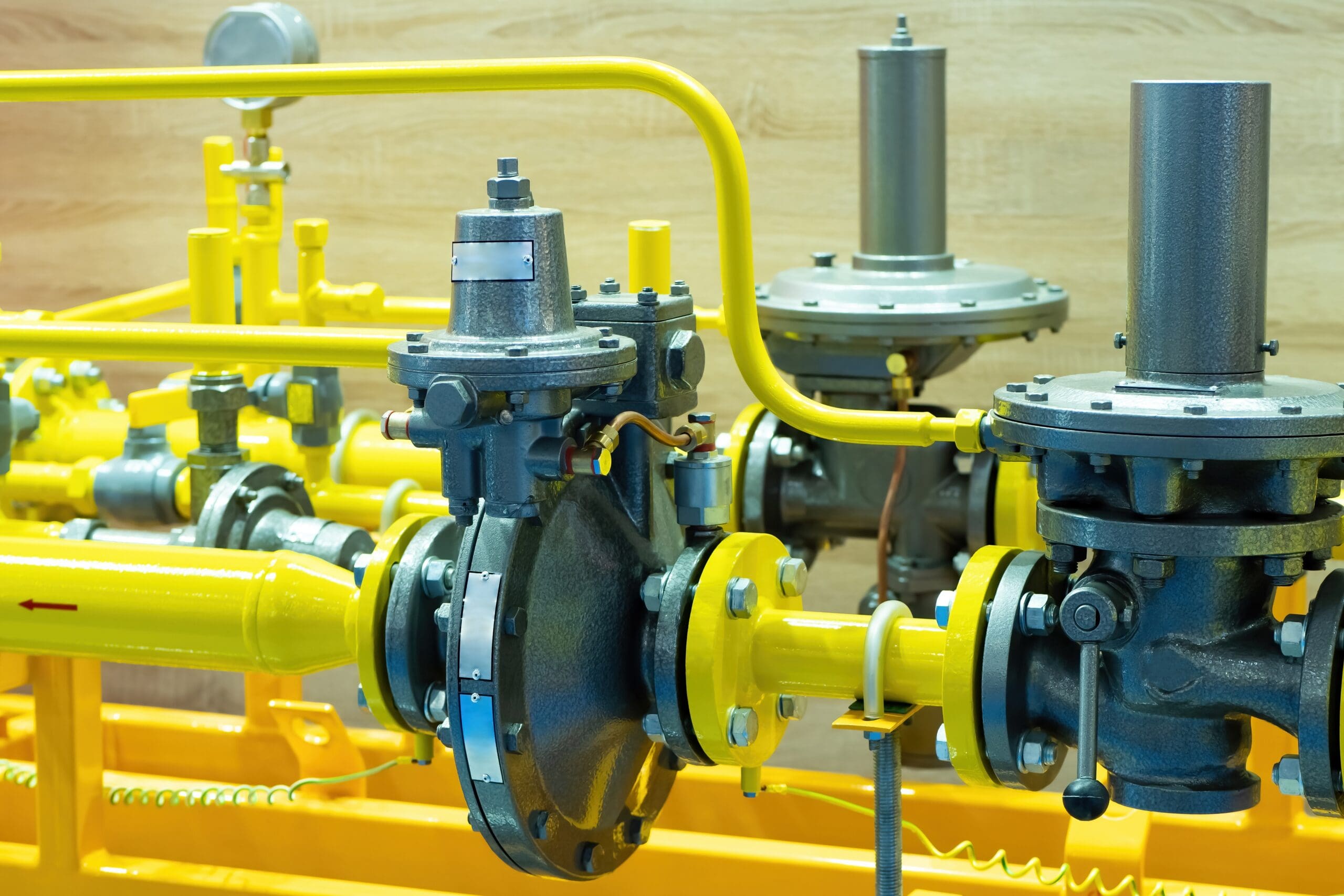

Fluid and process Control

Process & Fluid Control

Precision is paramount in fluid handling systems across industries. Our control valve seals, actuator diaphragms, regulator components, and pump elements deliver bubble-tight shutoff while withstanding aggressive chemicals, high pressures, and temperature extremes.

From standard O-rings to custom-engineered sealing solutions, we ensure system integrity, accuracy, and reliability in critical fluid control applications.

Industrial

Industrial Applications

Our general industrial solutions enhance equipment reliability, safety, and efficiency across manufacturing, mining, construction, and transportation sectors.

We produce vibration isolation mounts, sealing systems, environmental barriers, impact protection products, and flexible couplings engineered to extend equipment life and improve performance in demanding industrial environments.

Medical

Medical Devices

Patient safety drives our approach to medical component manufacturing. We produce biocompatible components for fluid delivery systems, surgical instruments, diagnostic equipment, respiratory devices, and wearable medical products.

We meet the exacting standards required for medical applications.

Oil & Gas

Oil & Gas

From downhole to downstream, our oil and gas components withstand extreme pressures, temperatures, and chemical exposure.

We engineer critical sealing elements for downhole tools, drilling equipment, wellheads, fracking operations, pipelines, valves, and processing facilities. Our specialized materials resist H₂S, CO₂, hydrocarbons, and abrasive conditions while maintaining seal integrity in the world's most demanding energy applications.

Transportation

Transportation

Across rail, maritime, automotive, and mass transit applications, our transportation components enhance safety, efficiency, and longevity.

We produce specialized elements for fuel systems, noise control, sealing systems, infrastructure, hull protection, and equipment mounts. With compliance to transportation industry standards and extensive testing capabilities, we ensure our components deliver reliable performance throughout extended service lives.

Water, Food and Beverage

Water, Food & Beverage

Food safety and sanitary design drive our solutions for water, food, and beverage processing.

From precision O-rings and gaskets to specialized components for meat processing, dairy equipment, sanitary pumps, filling systems, and thermal processing, our FDA-compliant materials maintain seal integrity while withstanding CIP/SIP cleaning protocols and meeting stringent regulatory requirements.