Rubber-to-Plastic Bonded Assemblies: Design and Manufacturing Considerations

Rubber-to-plastic bonded assemblies consist of an elastomer that is molded and chemically bonded to a prepared ...

Read More Rubber-to-Metal Bonded Assemblies: Design and Manufacturing Considerations

Rubber-to-metal bonded assemblies consist of an elastomer that is molded and chemically bonded to a clean ...

Read More Ventilator Products from The Rubber Group Help Fight COVID-19

The Rubber Group is making parts for ventilators, life-saving medical devices that are in high demand ...

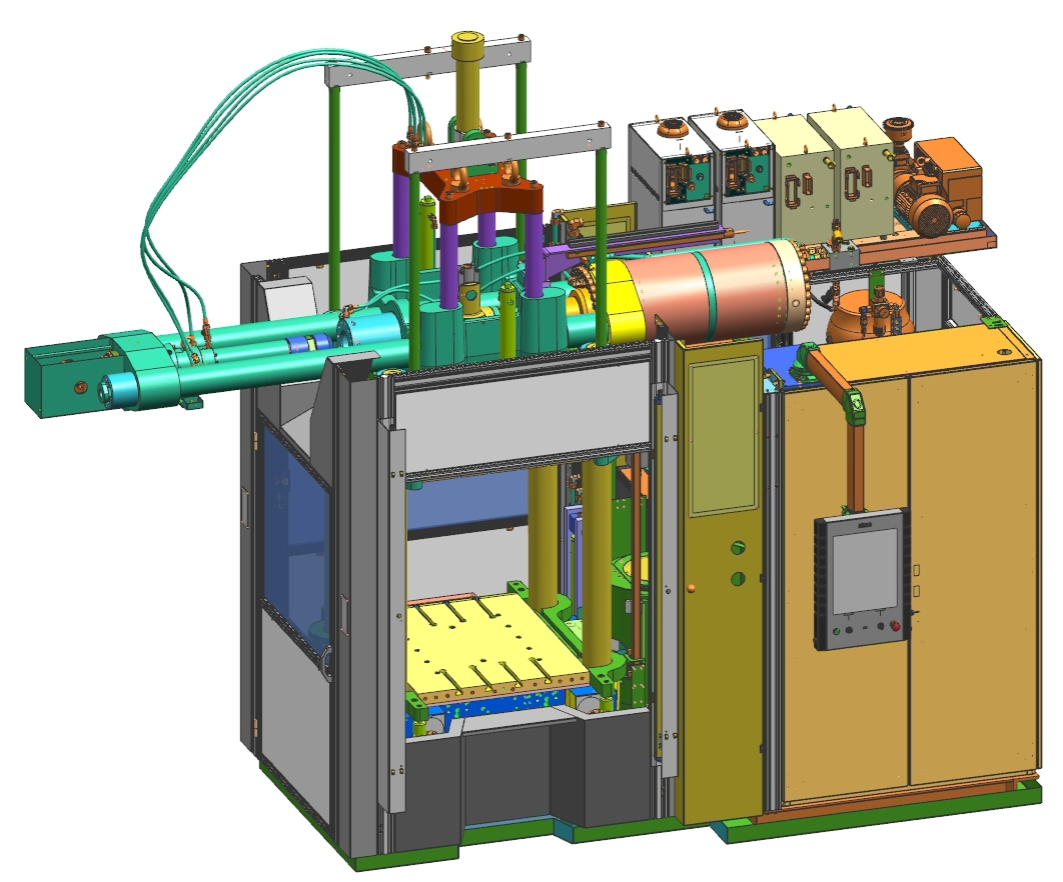

Read More The Rubber Group Adds Injection Molding Press for Larger Parts

The Rubber Group is using a new DESMA 968.400 ZO Benchmark (S2) rubber injection molding machine ...

Read More RPN Names The Rubber Group a Best Place to Work

Rubber & Plastics News (RPN), a leading trade publication for the rubber and plastics industry, has ...

Read More Maintenance Technician

The Rubber Group is seeking to hire a Maintenance Technician. *** $500 signing bonus after 90 ...

Read More Durometer vs. Modulus for Rubber Products

Durometer is a measure of a rubber’s resistance to indentation. More commonly, however, it’s known as ...

Read More The Rubber Group Continues to Ensure Customer Satisfaction by Upgrading to ISO 9001:2015

Company Background: The year was 1986 when George and Chuck Humphreys started The Rubber Group in ...

Read More FTIR Spectrometer with Microscope Identifies Materials, Solves Challenges

The Rubber Group is announcing its acquisition of an FTIR spectrometer and microscope that the rubber ...

Read More The Rubber Group Reduces Lead Times by Increasing Low-Tonnage Capacity for Injection Molded Products

The Rubber Group is announcing its acquisition of an injection molding machine that will reduce lead ...

Read More Ultra-Low Temperature FKM

Ultra-low temperature FKM is used in molded rubber products that need to withstand cold temperatures and ...

Read More - « Previous

- 1

- …

- 4

- 5

- 6