Markets

The Rubber Group makes power grid parts for electrical insulation and protection. Examples include molded rubber seals for transmission and distribution.

Read MoreLearn about Shore hardness and how to select the right rubber durometer for sealing your success in critical applications.

Read MoreSelecting the right silicone molding process for medical components is as important as material selection. TRG offers compression, transfer, and injection molding, and we can help you with process selection.

Read MoreSilicone molding is used to produce medical components such as surgical handles, sterilization tray mats, peristaltic pump tubing, umbrella valves, diaphragms, medical seals, and medical grommets. Many types of silicones are available, but they’re not all suitable for your medical application.

Read MoreThe Rubber Group makes custom molded rubber part for the oil and gas industry. Examples include valve seats, regulator seats, diaphragms, gaskets, and O-rings.

Read MoreTRG’s medical silicone complies with USP Class VI requirements for biocompatible elastomers that are safe for use when contact with human tissues and fluids is possible.

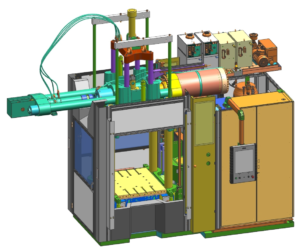

Read MoreThe Rubber Group uses a DESMA 968.400 ZO Benchmark (S2) for large part injection molding.

Read MoreThe Rubber Group (TRG) has acquired two more companies, SSRP and TEAM Products, and is adding capabilities that complement our custom rubber molding services.

Read MoreBulb seals help keep aircraft cabins pressurized. They also contain critical fluids within complex onboard equipment. These heroes of flight keep things tight.

Read MoreMedical handles that use rubber overmolding contribute to the safety of patients and the well-being of healthcare workers. They improve comfort and gripping.

Read More