Products and Services

Learn when to use compression molding, transfer molding, and injection molding. The Rubber Group provides all three rubber molding services can help you decide.

Read MoreThe Rubber Group is a bearing seal manufacturer that makes products which can extend service life and reduce maintenance costs.

Read MoreFor rubber components that operate in extreme environments, material selection is critical. High temperatures, aggressive chemicals, pressure fluctuations, UV exposure, and outdoor weathering can all cause premature failure if you specify the wrong elastomer. Whether you’re designing extruded rubber seals, custom gaskets, vibration isolators, or custom molded components, choosing the right compound upfront can significantly…

Read MoreThe Rubber Group makes power grid parts for electrical insulation and protection. Examples include molded rubber seals for transmission and distribution.

Read MoreThe Rubber Group provides rubber molding services and helps customers specify molding tolerances for part drawings.

Read MoreLearn about Shore hardness and how to select the right rubber durometer for sealing your success in critical applications.

Read MoreSelecting the right silicone molding process for medical components is as important as material selection. TRG offers compression, transfer, and injection molding, and we can help you with process selection.

Read MoreTransfer molding for rubber products is used in industries such as electronics, automotive, aerospace, and medical devices. This rubber molding process combines elements of compression molding and injection molding, but offers distinct advantages for applications where intricate shapes, insert molding, or high dimensional accuracy are required. The Rubber Group offers transfer molding services along with…

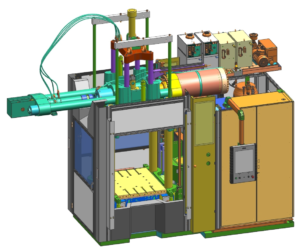

Read MoreThe Rubber Group uses a DESMA 968.400 ZO Benchmark (S2) for large part injection molding.

Read MoreThis PFAS Reporting Update contains information for manufacturers, importers, and other receivers of PFAS-containing elastomers like FKM, Viton, FVMQ, and FFKM.

Read More