Latest From us

The Rubber Group Blog

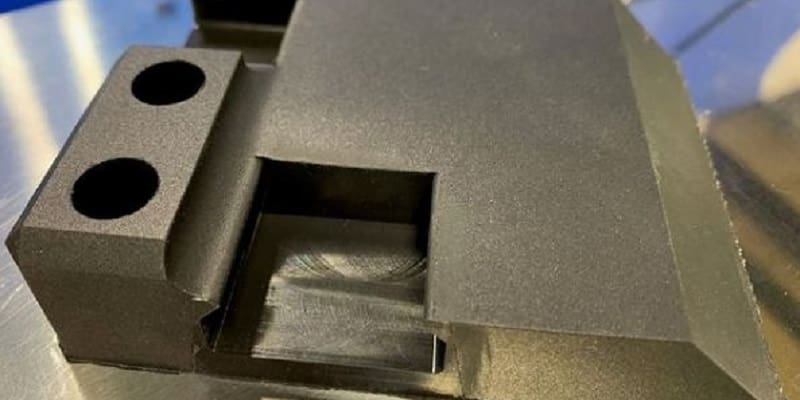

Compression Molding vs. Transfer Molding vs. Injection Molding

Bearing Seal Manufacturing for Rotating Equipment

How to Choose the Best Rubber Compound for Extreme Environments

Power Grid Parts for Electrical Insulation and Protection

Rubber Molding Tolerances

Shore Hardness: Selecting the Right Durometer for Critical Applications

Resources

Repository

Company Profile and Capablities

Learn about our history, certifications, and commitment to your success. From engineering and logistics through manufacturing and distribution, The Rubber Group is the industry leader in custom molded rubber products for major OEMs with names that you’ll recognize.

Chemical Compatibility

Find out which chemicals are compatible with natural rubber, SBR, GRS, butyl, EPR, EPT, EPDM, nitrile, Hydrin®, neoprene, Hypalon, urethane, polysulfide, silicone, fluorosilicone, and fluoroelastomers. From acetaldehyde to zinc sulfate, you’ll find the information that you need.

Molding Tolerances

Look up dimensional tolerances for A1 High Precision, A2 Precision, and A3 Commercial drawings from the Association for Rubber Product Manufacturers (ARPM) handbook. Each drawing designation includes millimeter and inch-based measurements for fixed and closure dimensions.