molding services

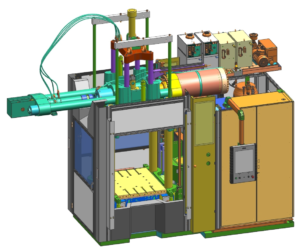

The Rubber Group uses a DESMA 968.400 ZO Benchmark (S2) for large part injection molding.

Read MoreDo you need rapid prototyping for molded rubber products? Compare The Rubber Group’s flexible, cost-effective approach to RTV molding and 3D printing.

Read MoreThe Rubber Group is making parts for ventilators, life-saving medical devices that are in high demand during the COVID-19 pandemic. The Rochester, New Hampshire company is manufacturing both new and existing products while leveraging its custom rubber molding, rubber-to-metal bonding, and die cutting capabilities. The Rubber Group is also producing complex molds rapidly and making…

Read MoreThe Rubber Group is using a new DESMA 968.400 ZO Benchmark (S2) rubber injection molding machine to produce larger parts such as insulators for power transformers. The rubber molder ordered the vertical injection molding press in the fall of 2019 and is already using it to produce large electrical insulators that separate conductors and prevent…

Read More