Rob Pruyn

The Rubber Group is making parts for ventilators, life-saving medical devices that are in high demand during the COVID-19 pandemic. The Rochester, New Hampshire company is manufacturing both new and existing products while leveraging its custom rubber molding, rubber-to-metal bonding, and die cutting capabilities. The Rubber Group is also producing complex molds rapidly and making…

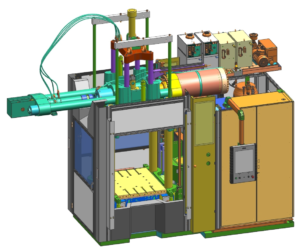

Read MoreThe Rubber Group is using a new DESMA 968.400 ZO Benchmark (S2) rubber injection molding machine to produce larger parts such as insulators for power transformers. The rubber molder ordered the vertical injection molding press in the fall of 2019 and is already using it to produce large electrical insulators that separate conductors and prevent…

Read MoreRubber & Plastics News (RPN), a leading trade publication for the rubber and plastics industry, has named The Rubber Group to its Best Places to Work List for 2019. The Rochester, New Hampshire manufacturer earned this award based on responses from its own employees to a survey conducted by Best Companies Group, an independent third-party.…

Read MoreThe Rubber Group is seeking to hire a Maintenance Technician. *** $500 signing bonus after 90 days *** Do you want to make a difference every day at your job? We are looking for a self motivated person to join our team and make us better. We are a local custom rubber molding that is…

Read MoreDurometer is a measure of a rubber’s resistance to indentation. More commonly, however, it’s known as a measure of hardness. Modulus, another material property, is the stress or force that’s required to produce a strain. Higher-durometer rubber usually has a higher modulus, but that doesn’t mean the relationship between durometer and modulus is straightforward –…

Read MoreCompany Background: The year was 1986 when George and Chuck Humphreys started The Rubber Group in Belleville, New Jersey as a distributor of molded rubber products. Then in 1991 the owners decided to move the company and its 5 employees to a less densely populated state, one where they felt had a better quality of…

Read MoreThe Rubber Group is announcing its acquisition of an FTIR spectrometer and microscope that the rubber molding company will use to identify compounds and analyze specific areas of interest. FTIR, an acronym for Fourier-transform infrared spectroscopy, supports the reverse engineering of rubber materials where the elastomer is unknown. FTIR spectroscopy and microscopy applications include the…

Read MoreThe Rubber Group Reduces Lead Times by Increasing Low-Tonnage Capacity for Injection Molded Products

The Rubber Group is announcing its acquisition of an injection molding machine that will reduce lead times by increasing capacity for products that require lower-tonnage injection. The new equipment, a REP G10 vertical injection molding machine, will also increase process control for precision products while supporting material and color changeovers that are both faster and…

Read More