Do you need help designing a rubber seal for injection, compression, or transfer molding? Then remember to account for these molding and material considerations.

Rubber Products in Different Sizes and Diverse Molding Capabilities

The Rubber Group uses injection, compression, and transfer molding to produced rubber products in sizes large and small. We have the rubber molding capabilities you need.

The Rubber Group Adds New Laser Marking Capabilities

The Rubber Group is announcing its acquisition of a new laser marking machine that can permanently mark parts for identification and traceability.

Rapid Prototyping for Molded Rubber Products

Do you need rapid prototyping for molded rubber products? Compare The Rubber Group’s flexible, cost-effective approach to RTV molding and 3D printing.

Medical Silicone Rubber Molding and Silicone Rubber Mold Materials

Many medical molding applications use silicones, but not all of these elastomers are right for your application. Learn about silicone selection.

Injection, Transfer and Compression Molding Explained

What are the advantages, disadvantages and differences between rubber injection molding, transfer molding, and compression molding? This article explains.

Rubber-to-Plastic Bonded Assemblies: Design and Manufacturing Considerations

Rubber-to-plastic bonded assemblies consist of an elastomer that is molded and chemically bonded to a prepared plastic surface using a specialized adhesive.

Rubber-to-Metal Bonded Assemblies: Design and Manufacturing Considerations

Rubber-to-metal bonded assemblies consist of an elastomer that is molded and chemically bonded to a clean metal surface using a specialized adhesive. During the injection, transfer, or compression molding process, rubber vulcanization and adhesive curing occur at the same time. Applications include small vibration mounts and massive railcar suspension components that weigh over 200 lbs. Chemical bonds can be strong, …

Ventilator Products from The Rubber Group Help Fight COVID-19

The Rubber Group is making parts for ventilators, life-saving medical devices that are in high demand during the COVID-19 pandemic. The Rochester, New Hampshire company is manufacturing both new and existing products while leveraging its custom rubber molding, rubber-to-metal bonding, and die cutting capabilities. The Rubber Group is also producing complex molds rapidly and making production tooling as quickly as …

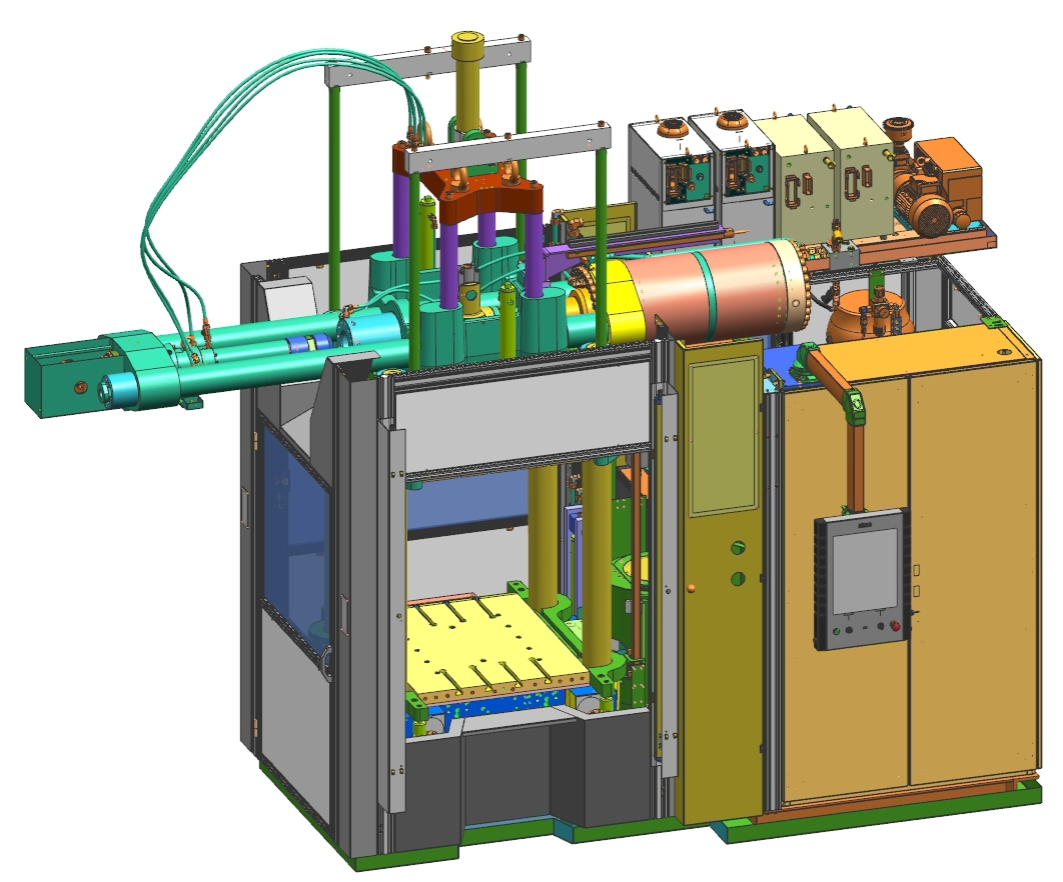

The Rubber Group Adds Injection Molding Press for Larger Parts

The Rubber Group is using a new DESMA 968.400 ZO Benchmark (S2) rubber injection molding machine to produce larger parts such as insulators for power transformers. The rubber molder ordered the vertical injection molding press in the fall of 2019 and is already using it to produce large electrical insulators that separate conductors and prevent the passage of current. DESMA, …